- Home

- Forging Services

- Forging Process

Forging

As a professional forging factory, JIANG DING provides high-quality forging services for aluminum and other metal materials. We specialize in OEM and ODM solutions with advanced technology and rigorous quality control. From our three international factories, we serve customers globally.

Forging Process

01

Material Selection (IQC)

Selecting the appropriate raw material. This is the first and the most critical step.

02

Cutting or Sawing

The raw material will be cut or sawed into the right size and shape for the intended product.

03

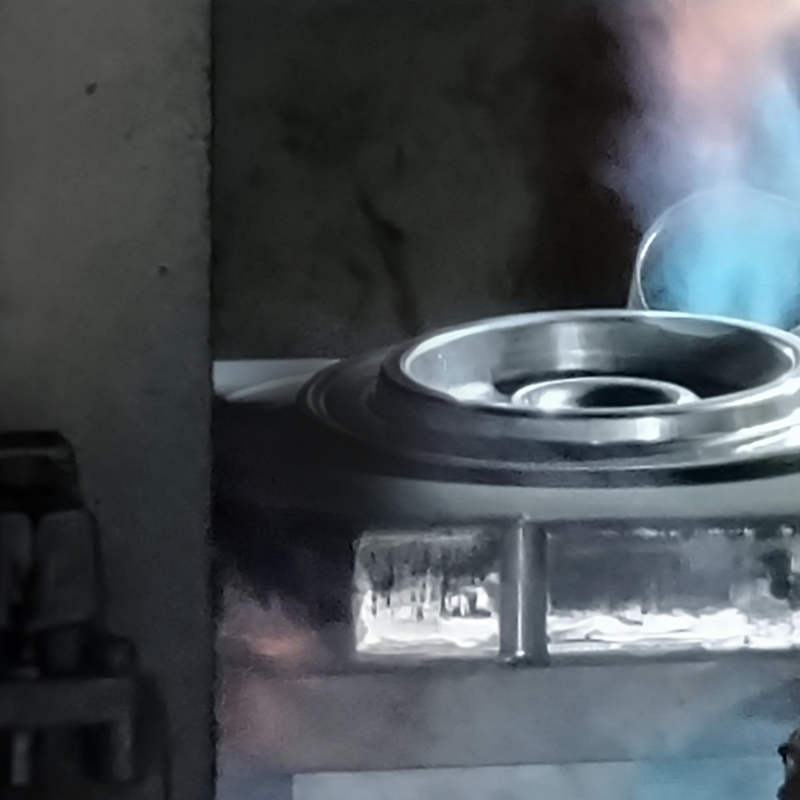

Pre-Heat

The cut materials are pre-heated to a specific temperature to make them more malleable for forging.

05

Heat Treatment

The forged pieces undergo heat treatment to alter their physical properties, improving strength and durability.

06

Trimming

Excess material from the forging process is trimmed away to achieve the final desired dimensions and shape.

07

CNC Machining Process

The parts are then processed using CNC machines, such as turning and grinding.

08

Surface Treatment

Surface treatments such as polishing, coating, or anodizing enhance the appearance and resistance to corrosion and wear.

09

Quality Control

Rigorous quality control inspections are conducted to ensure each forged piece meets the required standards before shipment.

10

Packaging For Shipment

Finally, the finished products are carefully packaged and shipped to the customers.

professionalism,

integrity, responsibility,

& service

Advantages of Jiang Ding’s Forging Services

OEM

JIANG DING offers outstanding OEM services with extensive experience in metal mold flow analysis, comprehensive material knowledge, and optimal forging performance. This ensures that the final products meet high-quality standards and perform reliably in their intended applications.

Nearby

JIANG DING has established factories in three different countries, allowing them to serve customers locally. This strategic placement minimizes lead times, reduces shipping costs, and improves customer service.

QC Process

We employ a thorough quality control process, which includes three inspection procedures (independent inspection, spot checking, final inspection), penetrant testing to detect surface defects in forged parts and a fluorescence laboratory for detailed analysis. These measures are in place to guarantee the highest quality and reliability of our final products.

Responsibility & Service

To meet customer needs. Further, it creates a win-win corporate community of "customers, employees, shareholders, and manufacturers."

Contact Us

Transform Your Designs into Reality with Our Expert Forging Solutions. Get in Touch Now!

Get In Touch